Hannukainen Mining's goal is to make the Kolari mine as clean as possible

The goal of Hannukainen Mining is to make the Kolari mine as clean as possible. Mine planning is a longterm activity. The operation is based on solutions proven to be safe. During the operations, we will seek to develop new solutions and models that can be productised and used in other mines around the world.

”We test, pilot, study, and develop water treatment for as long as needed to be certain that the discharge water from the mine is not harmful to the environment.”

The construction of a protective wall between the mine site and the houses along Äkäsjoki river will reduce the noise, dust, and pressure wave effects as well as reduce the risk of flying rocks.

At the border of the mine site closest to the village of Hannukainen, a protective wall will be built. As a result, noise and dust from the mine will not exceed the noise and dust limits set by the government.

The protective wall will be built using overburden – such as moraine, stripped from the mining area. The slopes of the protective wall is planned to to have a gradient of 1:2-

1:3. The most significant landscape effect of the protective wall is focused on the Hannukainen village, where the new large element will at times be located quite near the inhabited area.

Viewed from Ylläksentie, the protective wall will mainly be left in a blind spot due to the terrain and trees. The protective wall will not be extensively visible from roads further away than the Hannukainen village. When travelling along Ylläksentie towards Hannukainen, drivers may be able to see the protective wall close to Puukonniva, for about two kilometres before the road descends towards Äkäsjoki.

The protective wall will only be visible within a narrow area, and the wall is no higher than other elements in the landscape. In a landscape seen from far away, the protective walls may sometimes be seen from high and open viewing locations, such as the top and western hillside of Ylläs and Kuertunturi.

LENGTH: 3,340 m

WIDTH: 60-185 m

HEIGHT: 6-35 m

A transportation corridor approximately nine kilometres long and 8.5 metres wide will be built to connect the mine and the concentration plant to transport ore. The route for the conveyor from the Hannukainen mine to the Rautuvaara concentration is part of the mining concession. The conveyor will start from an underground crusher at the mine in a 700-metre-long rock tunnel. The conveyor will be lifted higher to pass over Pakasaivontie, Sorakuopan tie, and a summer cottage road (Rautuojantie).

An underpass will be built for the conveyor at Ylläksentie and Äkäsjoentie. Passage ways under the conveyor will be built at Valkeajoki, Äkäsjoki, Rautuoja and two swamp

areas.

The conveyor will also be lifted higher for reindeer and forest machines on dry forest ground in Rautuvaara. The implementation and location of the underpasses has

been agreed on together with reindeer herders, Metsähallitus, and forest owners.

”The belt conveyor will be covered and protected by side walls to reduce dust emissions and noise.”

The conveyor is a new element, visible in the immediate landscape.The surroundings of the belt conveyor where most people move around, are the roads Ylläksentie and

Äkäsjoentie. At these locations, the conveyor goes under the roads, and is therefore not a particularly visible element in the landscape.

There will be road junctions built for the service roads of the conveyor, which will cause local modifications to the terrain. The highest points for the conveyor from the ground are the bridges crossing Pakasaivontie and Sorakuopantie. There, the maximum height of the bridge is 8.25 m. Lower road bridges cross other roads, rivers, swamps, and a reindeer area. The bridge crossing Äkäsjoki river has the greatest effect on how the landscape is perceived, because it is located close to holiday houses along the river and when the river is in recreational use. With the exception of tunnels and bridges, the conveyor follows the surface profile of the terrain.

A noise study has been conducted on the belt conveyor. Based on the modelling results, the average night-time noise levels of the belt conveyor and other mining activities

are, in holiday homes in the area under study, no more than 34 dB, and in permanent residences 26 dB, and thus below the night-time reference values.

In the conveyor area, the difference between the average noise levels during the day and night is very small (less than 1 dB), so the daytime reference values are also well below the accepted ones.

In February, 2018, Hannukainen Mining concluded a partnership agreement with Teollisuuden Vesi Oy, which has long experience of treating mine and industrial water, as well as expertise in microbiology. Through the partnership agreement, the planning of water treatment in for the Hannukainen mine now includes world-class water treatment expertise. The goal is to find solutions that reduce the content of harmful substances to the extent that they become insignificant.

The calculations in the environmental permit application, for example, have become more specific as cooperation has begun between Teollisuuden Vesi and Hannukainen Mining.

Water treatment planning is based on the lowest possible clean water usage in the process and water recycling within the concentration plant by means of clarification and

thickening.

The emissions load of sulphate will be at its highest in very rainy years. In years with little rain, sulphate loads are low. That is why water treatment plans must be taken into account and the environmental effects must be examined in the long run.

”Exposure to sulphate, for example when swimming, does not pose a risk to users of the water system.”

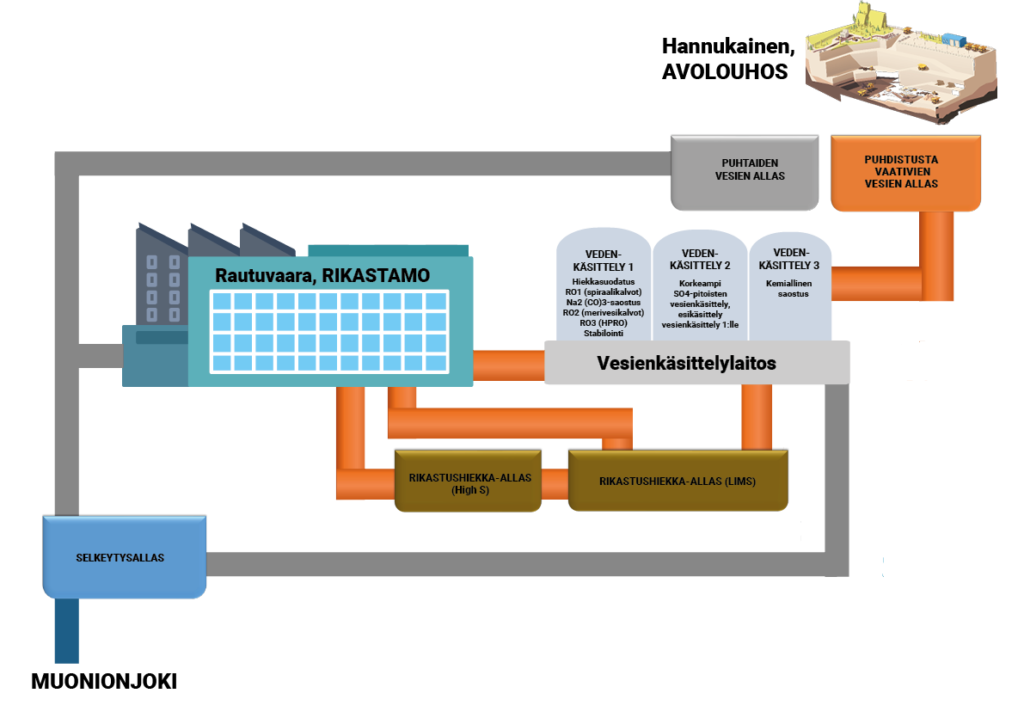

The ore mined from the open pits at Hannukainen and Kuervitikko is concentrated at Rautuvaara. The concentration process consists of multi-phase grinding and flotations, magnetic separation, thickening of solids, and filtering of concentrates. Chemicals used in the concentration process include:

The desired characteristics for air bubbles transporting minerals in Efficient use of water flotation, is obtained from foaming agents. Collectors make certain minerals stick to air bubbles during flotation and thereby separate them from other solids. Scavengers, for their part, prevent certain minerals from sticking to air bubbles. In addition, the flotation features of different minerals can be affected by adjusting the pH. In addition to the aforementioned chemicals, flocculants are used in the thickening of solid matter.

The process at the concentration plant requires little water from outside the mining area. Most of the water needed is obtained from internal circulation as the excess from the thickening of solids carried out at different stages of the process.

In addition to this internally circulating water, the process takes approximately 100 m3/h of water from the clarification pond, which is mainly water pumped from the open pits. By using only a small amount of water from outside the concentration plant, it is possible to minimise the effects on the surrounding water systems, because this also means that the amount of water removed from the plant can be kept low. All the water removed from the water circulation of the concentration plat is purified.

”All the water removed from the water circulation of the concentration plat is purified.”